Answer list for Super wedge rock splitter for excavator

12 Jul 2024

1. Does the rock splitter need a free face to split rock?

A stonemason needs a free face to divide the stones.

2. Do you have any experience in trench making, if so, how is the process or best way to do it?

Experience in making trenches: First, create a free surface (with a depth of 1300mm or more, a width equal to the width of the trench, and a length of 1000mm or more), then drill holes according to the appropriate spacing, and use a splitting machine to split the rock. After splitting 2-3 rows of holes, the cracked rock must be cleaned up. According to the required depth of the trench, split the rock layer by layer until the desired depth of the trench is achieved.

3. what is the wear of the splitter. Do you have to change the wedges every “X” number of cubic meters of rock?

The wedge set ( one centre wedge+two counter wedges ) needs to replace wedges every 3000 cubic meters of rock.

4. What is the most recurring failure?

The most common faults are improper hole spacing or insufficient lubricating grease on the wedges, which may cause the wedges to get stuck.

5. What is the hydraulic requirement or size of the excavator?

Excavators weighing over 13 tons are acceptable.

6. Can you split reinforced concrete?

Can split reinforced concrete.

7. What is the cost of the hydraulic piston and seals?

The price of hydraulic pistons and seals is @$160.00 / set by EXW.

8. What is the grease or lubrication for the wedges? Do you provide a proprietary grease, or any grease can lubricate?

The lubricating oil or lubricant for the wedge is high-grade molybdenum disulfide grease. We provide proprietary lubricating grease, any grease can lubricate, but the lubrication effect is different.

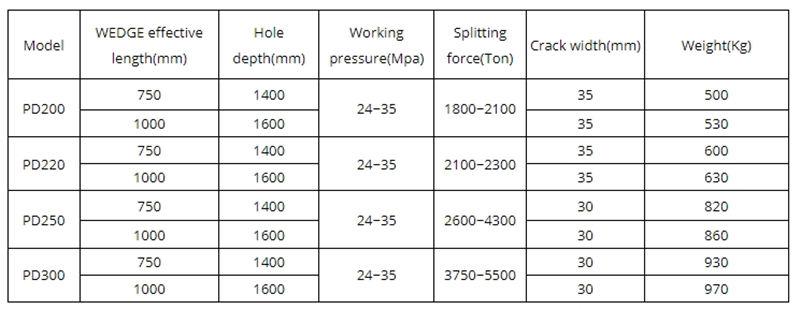

Technical Date Sheet

9. What is the whole diameter, depth and drill hole spacing for your range of splitters?

The overall diameter of the jump super wedges splitting machine mainly includes a cylinder diameter of 250mm and a cylinder diameter of 300mm. The drilling depth of 750 type wedges ( 750mm is wedge length ) is over 1300 millimeters, and the drilling depth of 1000 type wedges is over 1550 millimeters. Generally, it is required to set splitting points (drilling spacing) that meet the following two points:

A、 Reasonable drilling spacing, reduced spacing between hard rocks, and increased spacing between soft rocks;

B、 The drilling depth shall not be less than 1300 millimeters (wedge type750).

The specific setting data in Article A is empirical data, which is determined through practice based on the strength of the rock and the condition of the free face. The spacing between hard rock boreholes with a strength of 1300-1600kg/c ㎡ is 700mm, the spacing between quasi hard rock boreholes with a strength of 1000-1300kg/c ㎡ is 800-900mm, and the spacing between soft rock boreholes with a strength of 1000kg/c ㎡ is 1000-1200mm.

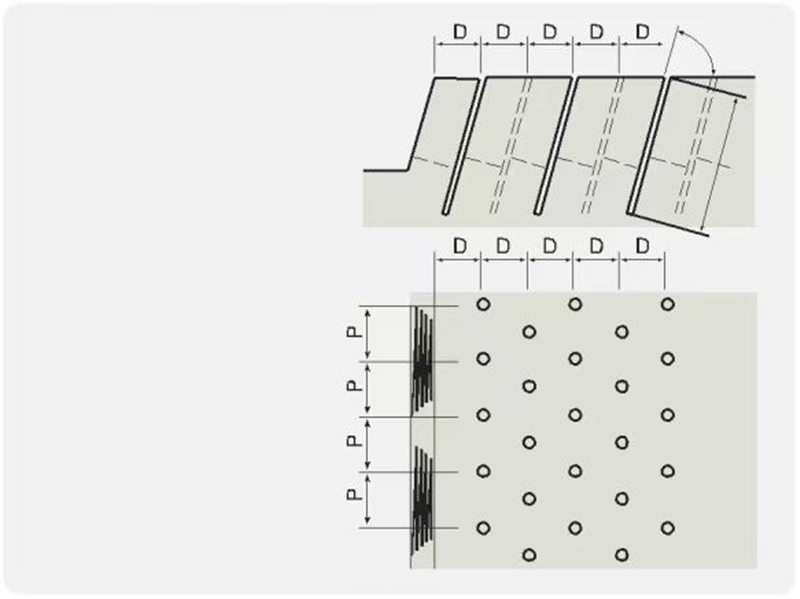

Row spacing (D)=700~1200mm hole spacing (P)=1000~1200mm. The force of a cylinder diameter of 300mm is greater than that of a cylinder diameter of 250mm, and the drilling spacing is larger. As shown in the following diagram:

10. Value of the spare parts wedge kit?

The wedge kit for parts price @$1250.00/ set (2 side counter wedges+1 middle centre wedge ). price is quoted by EXW.

11. What is the cost of the large Rock Splitter?

EXW price of a large jump super wedges model no : PD250@$8700,00 , (cylinder diameter 250 mm) and PD300 @$9600.00 /pcs (cylinder diameter 300 mm), both of which are prices for installing 750 type wedges.

12. For a fleet of rock splitters for rent, what is the durability, possible breack points and critical spare parts we would need?

For leased over sized jump super wedges rock splitting machines for excavator, the durability is very good (except for wedges), and the possible fracture points are wedges (including edge wedges and middle wedges) and cylindrical pins (used for connecting middle wedges). Key spare parts of PD300, such as edge wedges and middle wedges price @$1300.00 / set per set, and cylindrical pins price $60.00/ pcs by EWX.